Here's how to pick a bit based on three basic bits: material, coating and geometric features.

01, how to choose the material of the drill

Materials can be roughly divided into three types: high speed steel, cobalt high speed steel and solid carbide.

High speed Steel (HSS) :

High-speed steel has been used as a cutting tool for more than a century since 1910. It is the most widely used and the cheapest cutting tool material available today. High-speed steel bits can be used both on hand drills and in more stable environments such as drilling presses. Another reason for the durability of high-speed steel may be that its tools, which can be repeatedly sharpened, are cheap enough to be used not only as drill bits but also as turning tools.

Cobalt high speed Steel (HSSE) :

Cobalt-containing high speed steel has better hardness and red hardness than high speed steel. The increase in hardness also increases wear resistance, but at the same time, some toughness is sacrificed. Like high speed steel, they can be polished to improve their use.

CARBIDE:

Cemented carbide is a composite material of metal base. Among them, tungsten carbide is used as the matrix, and some materials of other materials are used as adhesives through a series of complex processes such as hot isostatic pressing for sintering. In hardness, red hardness, wear resistance and other aspects compared with high speed steel, there is a huge improvement, but the cost of carbide tool is also more expensive than high speed steel. Cemented carbide in tool life and processing speed than the past tool materials have more advantages, in the repeated grinding tool, the need for professional grinding tools.

02, how to choose the bit coating

The coating can be roughly divided into the following 5 types according to the range of use.

Uncoated: Uncoated cutting tools are the cheapest, usually used for processing aluminum alloy, low carbon steel and other soft materials.

Black oxide coating: oxidation coating can provide better than uncoated tool lubricity, has better oxidation resistance and heat resistance, and can improve on the service life of more than 50%.

Titanium nitride coating: Titanium nitride is the most common coating material, is not suitable for processing high hardness and high processing temperature materials.

Titanium carbon nitride coating: Titanium carbon nitride is developed from titanium nitride, has higher temperature resistance and wear resistance, usually purple or blue. Used in Haas's workshop to make cast-iron workpieces.

Aluminum nitride titanium coating: coating aluminum nitride titanium than all of the above are high temperature resistant, so can use at higher cutting conditions. Such as processing superalloys. It is also suitable for the processing of steel and stainless steel, but because it contains aluminum elements, chemical reactions will occur in the processing of aluminum, so it is necessary to avoid the processing of materials containing aluminum.

In general, a cobalt bearing drill with a titanium carbonitride or titanium nitride coating is a more economical solution.

03. Geometric characteristics of the drill bit

Geometric features can be divided into the following three parts:

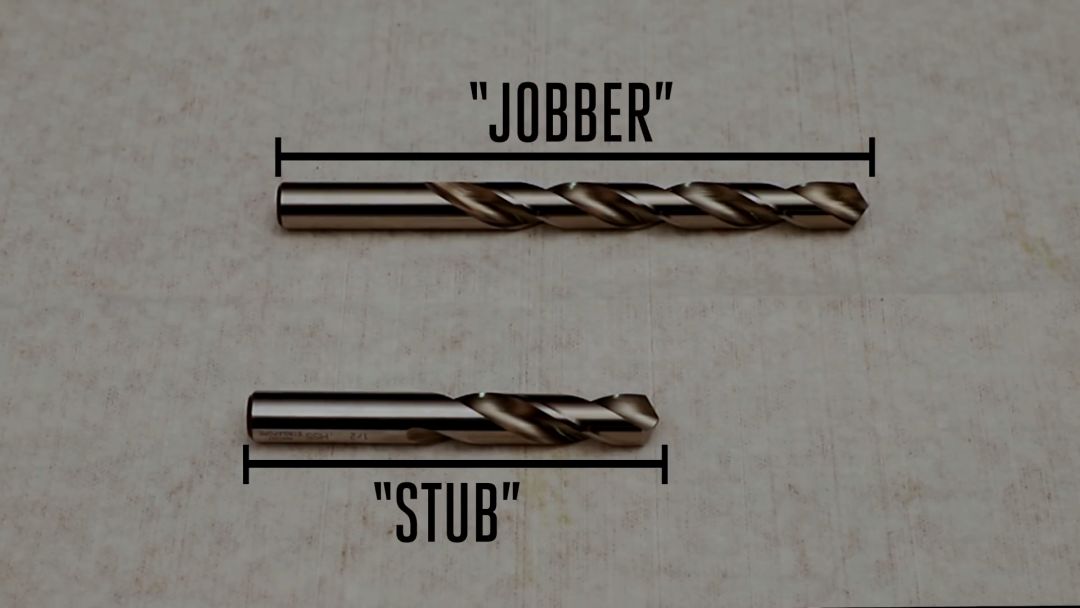

The length

The ratio of length to diameter is called diameter doubling, and the smaller the diameter, the better the rigidity. Choosing a bit with the right edge length for chip removal and the shortest overhang length can improve machining rigidity, thereby increasing tool life. Insufficient edge length is likely to damage the drill bit.

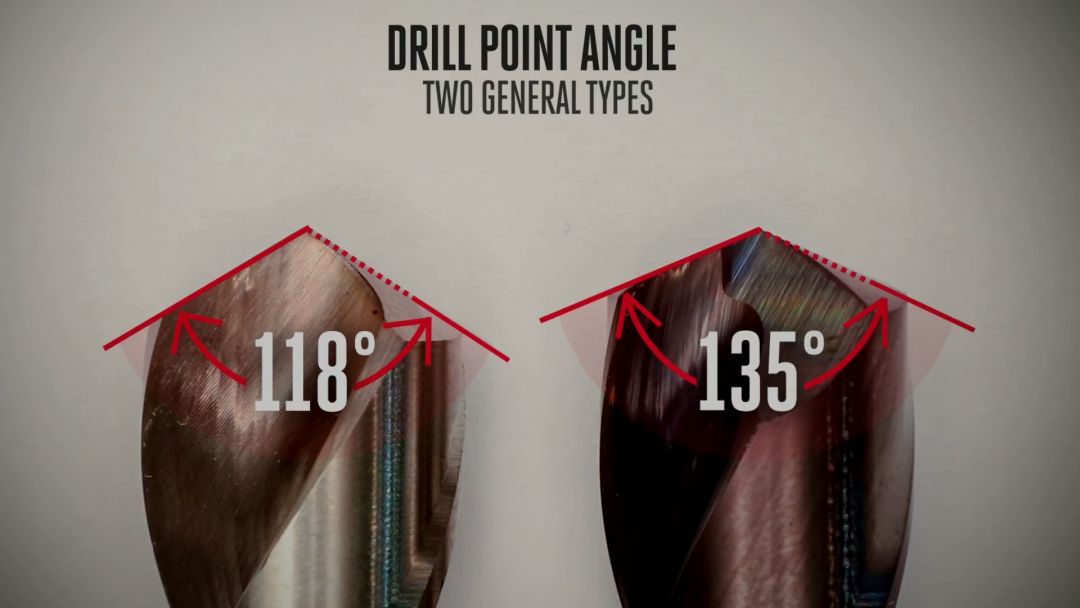

Drill tip Angle

The drill point Angle of 118° is probably the most common in machining and is commonly used for soft metals such as mild steel and aluminum. This Angle design is usually not self-centering, which means that the centering hole must inevitably be machined first. The 135° drill tip Angle is usually self-centering, which saves a lot of time by eliminating the need to process a single centering hole.

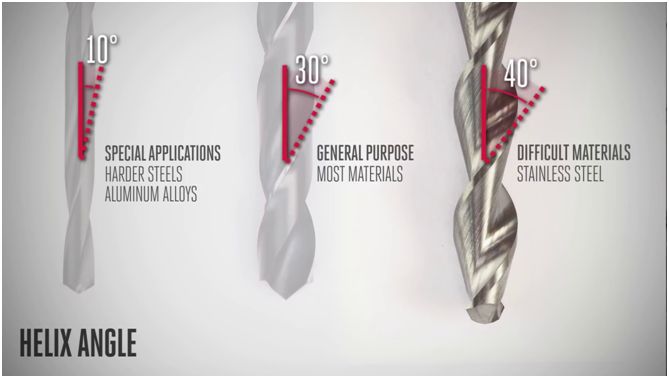

Spiral Angle

A 30° spiral Angle is a good choice for most materials. However, for environments where cuttings are better removed and cutting edges are stronger, a bit with a smaller spiral Angle can be selected. For hard-to-work materials such as stainless steel, a design with a larger spiral Angle can be used to transfer torque.

Post time: Sep-01-2022