A, when the need for grinding:

1. Sawing quality does not meet the requirements, such as the product surface burr, rough, need to immediately grinding.

2. When the blade of the alloy is worn up to 0.2mm, it must be sharpened.

3. Push material hard, paste

4. Produce abnormal sound

5. The saw blade has sticky teeth, tooth loss and tooth collapse when cutting

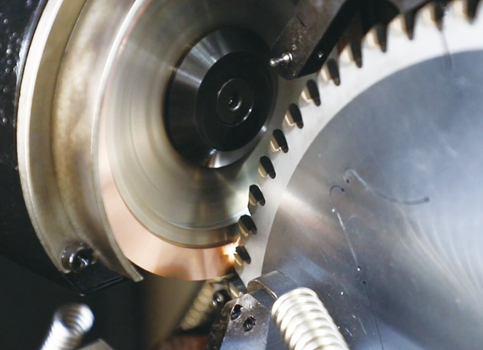

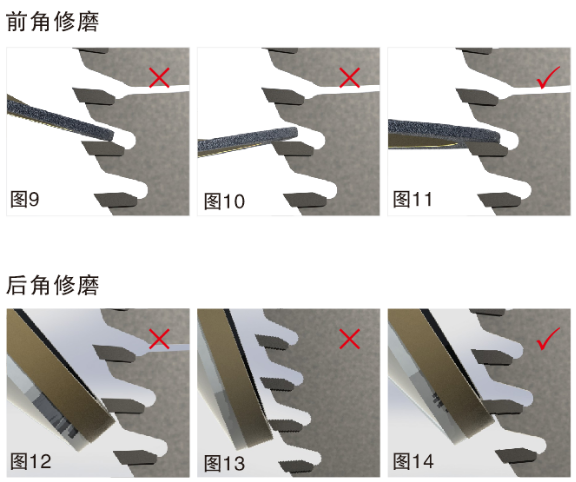

Two, how to grind:

1. The grinding is based on the back of the grinding teeth, the front of the grinding teeth is paved, and the side of the teeth is not grinding without special requirements.

2. The condition that the front and rear angles remain unchanged after grinding is that the Angle between the grinding wheel working face and the front and rear tooth surfaces to be grinding is equal to the grinding Angle, and the distance moved by the grinding wheel is equal to the grinding amount. Make the working face of the grinding wheel parallel to the serrated surface to be ground, and then gently contact the working face of the grinding wheel, and then make the working face of the grinding wheel leave the tooth surface. Then adjust the working face Angle of the grinding wheel according to the grinding Angle, and finally make the working face of the grinding wheel contact with the tooth surface.

Three, grinding matters needing attention

1. Before grinding, the resin and debris on the saw blade must be removed.

2. The grinding shall be carried out in strict accordance with the original geometric design Angle of the saw blade to avoid the damage of the tool caused by improper grinding. After finishing the grinding, it must be inspected and qualified before it can be put into use to avoid personal injury.

3. If manual grinding equipment is used, it is necessary to have an accurate limit device, and to detect the tooth surface and tooth top of the saw blade.

4. In the grinding need to use special coolant on the grinding lubrication cooling, otherwise it will reduce the service life of the tool and even cause the alloy tool head internal cracking leading to the use of dangerous situation.

Post time: Sep-08-2022