As a common tool for processing internal threads, the tap can be divided into spiral groove tap, edge dip tap, straight groove tap and pipe thread tap according to the shape, and can be divided into hand tap and machine tap according to the operating environment, and can be divided into metric tap, American tap and British tap according to specifications. Taps are also the main processing tools used in tapping. So how to choose the tap? Today I share with you a tap selection guide to help you choose the right tap.

Tap classification

A. Cutting taps

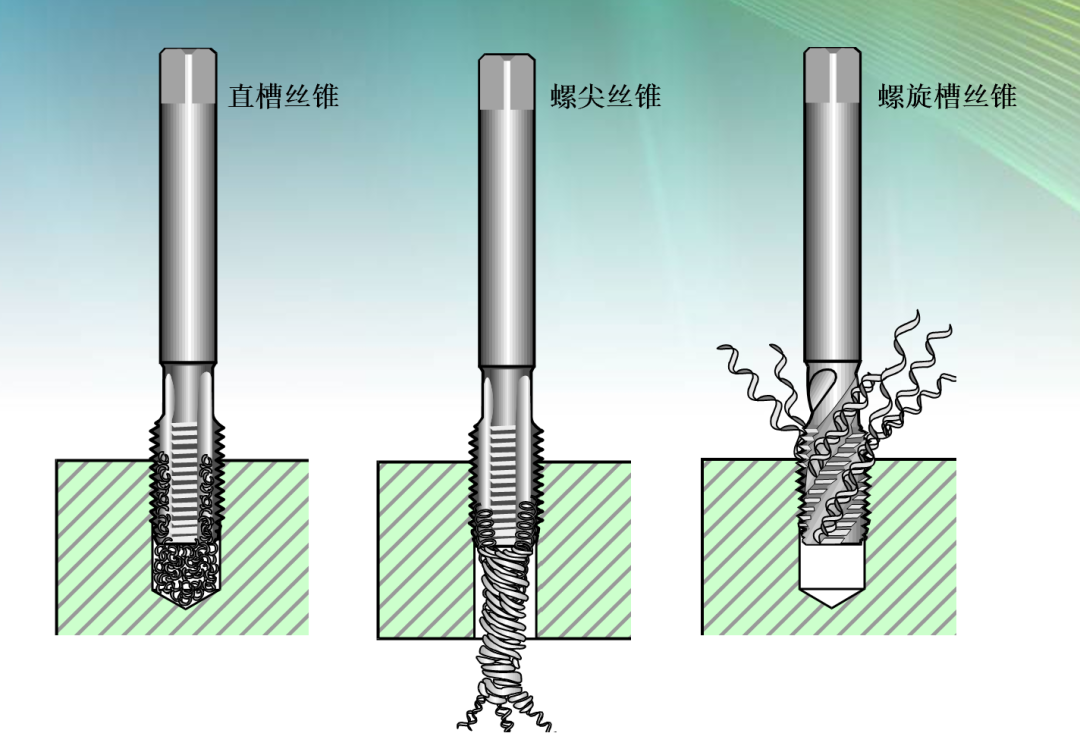

1, straight slot tap: used for through hole and blind hole processing, iron filings exist in the tap slot, the quality of the processed thread is not high, more commonly used in the processing of short chips, such as gray cast iron and so on.

2, spiral groove tap: used for hole depth less than or equal to 3D blind hole processing, iron filings along the spiral groove discharge, high thread surface quality.

10~20° spiral Angle tap can be processed with thread depth less than or equal to 2D;

The 28~40° helical Angle tap can process the thread depth less than or equal to 3D;

The 50° spiral Angle tap can be used to process the thread depth less than or equal to 3.5D (4D under special working conditions).

In some cases (hard materials, large tooth pitch, etc.), in order to obtain better tip strength, spiral groove taps will be used to process through holes.

3, screw tip tap: usually can only be used for through hole, length to diameter ratio of up to 3D~3.5D, iron chip down discharge, cutting torque is small, the surface quality of the thread is high, also known as edge dip tap or tip tap.

When cutting, it is necessary to ensure that all cutting parts are penetrated, otherwise there will be tooth collapse.

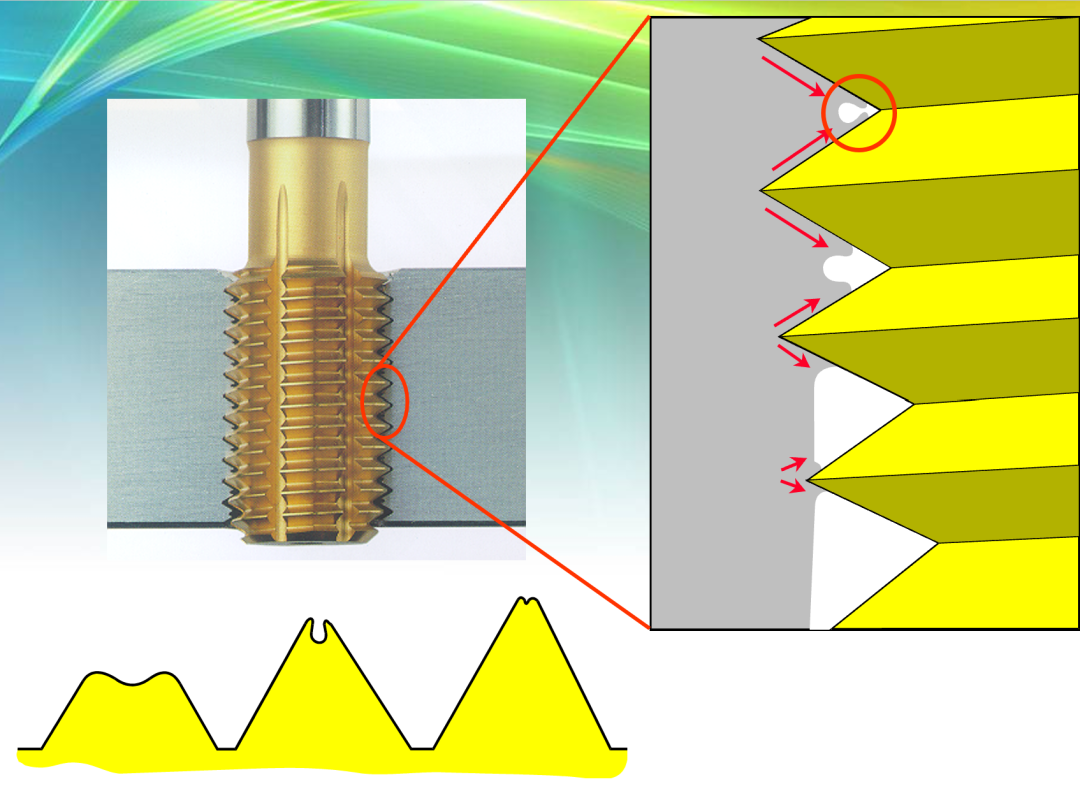

B. Extrusion tap

It can be used for processing through hole and blind hole, forming tooth shape through plastic deformation of material, and can only be used for processing plastic material.

Its main features:

1, using the plastic deformation of the workpiece to process the thread;

2, the cross-sectional area of the tap is large, high strength, not easy to break;

3, the cutting speed is higher than the cutting tap, and the productivity is also improved accordingly;

4, due to the cold extrusion processing, the mechanical properties of the thread surface after processing are improved, the surface roughness is high, the thread strength, wear resistance, corrosion resistance is improved;

5, no chip processing.

The disadvantages are:

1, can only be used for processing plastic materials;

2. High manufacturing cost.

There are two structural forms:

1, no oil groove extrusion tap is only used for blind hole vertical addition;

2, with oil groove extrusion tap is suitable for all working conditions, but usually small diameter taps due to the difficulty of manufacturing do not design oil groove.

Structural parameters of taps

A. Shape and size

1. Total length: attention should be paid to some working conditions requiring special lengthening

2. Slot length: on

3. Handle side: At present, the common standard of handle side is DIN(371/374/376), ANSI, JIS, ISO, etc., when selecting, attention should be paid to the matching relationship with the tapping tool handle

B. Threaded part

1, precision: by the specific thread standard to choose, metric thread ISO1/3 level is equivalent to the national standard H1/2/3 level, but need to pay attention to the manufacturer's internal control standards.

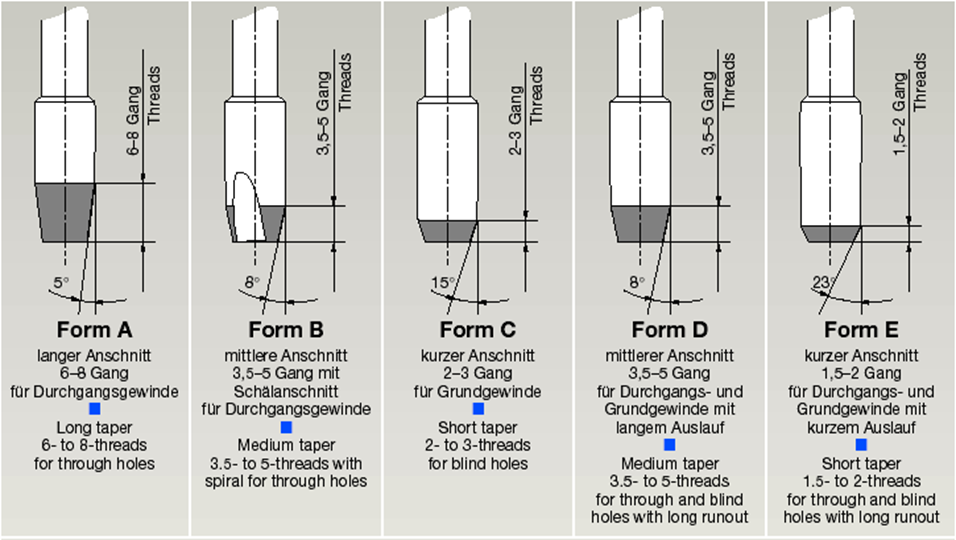

2, cutting cone: the cutting part of the tap, has formed a partial fixed mode, usually the longer the cutting cone, the better the life of the tap.

3, correction teeth: play the role of auxiliary and correction, especially in the tapping system is not stable working conditions, the more correction teeth, the greater the tapping resistance.

C. Chip removal trough

1, groove type: affect the forming and discharge of iron filings, usually for each manufacturer's internal secrets.

2. Front Angle and rear Angle: when the tap becomes sharp, the cutting resistance can be significantly reduced, but the strength and stability of tooth tip decrease. The rear Angle is the rear Angle of shovel grinding.

3, the number of slots: the number of slots increases the number of cutting edges increases, can effectively improve the tap life; But will compress the chip removal space, in the chip removal disadvantage.

Post time: Sep-14-2022