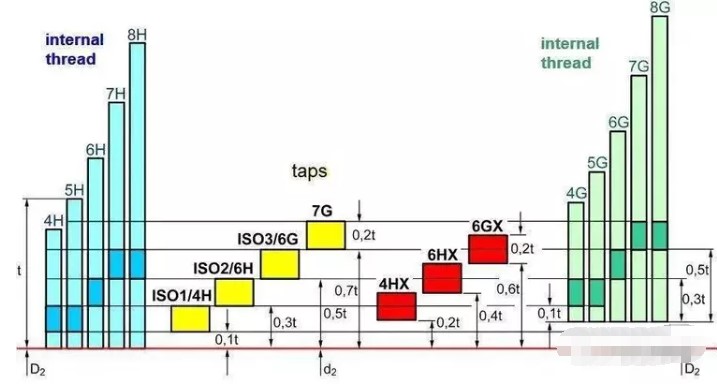

1. Tolerances for taps of different precision grades

The accuracy level of the tap can not be selected and determined only according to the accuracy level of the thread to be machined, It should also consider:

(1) the material and hardness of the workpiece to be machined;

(2) Tapping equipment (such as machine tool conditions, clamping tool handles, cooling rings, etc.);

(3) Precision and manufacturing error of the tap itself.

For example: processing 6H thread, when processing on steel parts, 6H precision tap can be selected; In the processing of gray cast iron, because the middle diameter of the tap wear faster, the expansion of the screw hole is also small, so it is appropriate to choose 6HX precision tap, life will be better.

Description of the precision of the JIS tap:

(1) Cutting tap OSG uses OH precision system, different from ISO standards, OH precision system will force the width of the entire tolerance zone from the lowest limit, every 0.02mm as an accuracy level, named OH1, OH2, OH3, etc.;

(2) Extrusion tap OSG uses the RH accuracy system, the RH accuracy system forces the width of the entire tolerance zone to start from the lowest limit, every 0.0127mm as an accuracy level, named RH1, RH2, RH3 and so on.

Therefore, when using the ISO precision tap to replace the OH precision tap, it can not be simply considered that 6H is about equal to OH3 or OH4 level, which needs to be determined by conversion, or according to the actual situation of the customer.

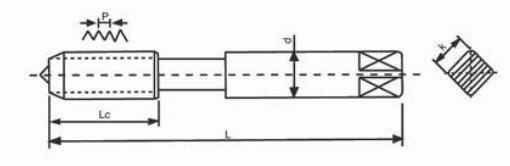

2. External size of tap

(1) At present, the most used are DIN, ANSI,ISO, JIS, etc.;

(2) Select the appropriate total length, blade length and handle square size according to different processing requirements or existing conditions of customers;

(3) Interference during processing.

3. The 6 basic elements of tap selection

(1) Type of thread processing, metric, British, American, etc.;

(2) Type of thread bottom hole, through hole or blind hole;

(3) Material and hardness of the workpiece to be machined;

(4) The depth of the complete thread of the workpiece and the depth of the bottom hole;

(5) The precision required by the workpiece thread;

(6) Shape standard of tap.

Post time: Oct-31-2023