Free sample for Round Die - HSS DIN345 Morse Taper Shank Drills – YUXIANG

Free sample for Round Die - HSS DIN345 Morse Taper Shank Drills – YUXIANG Detail:

Product description

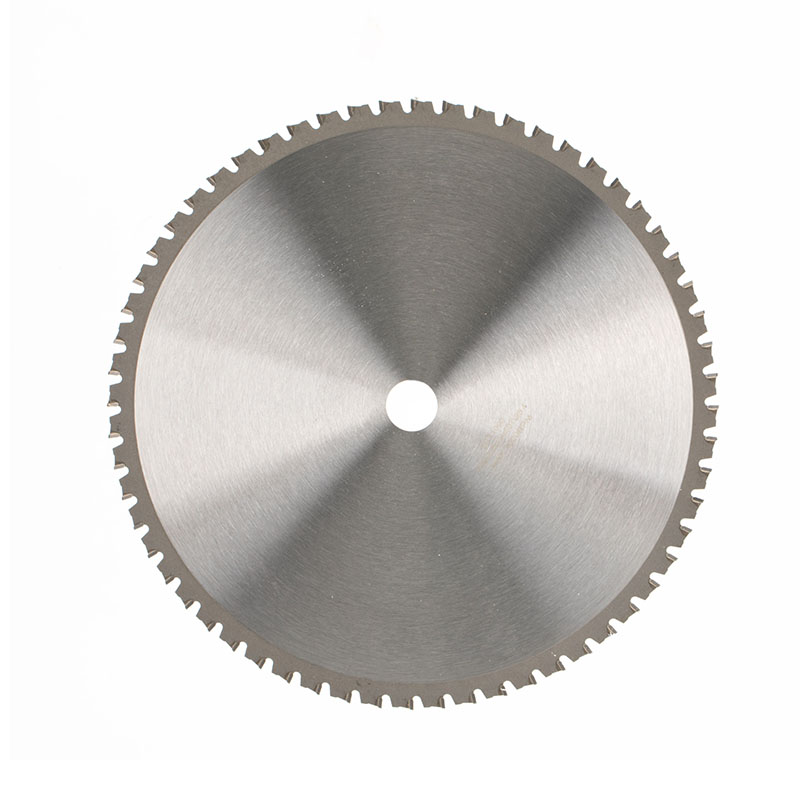

The die is equivalent to a nut with high hardness. There are several chip removal holes around the screw hole. Generally, cutting cones are ground at both ends of the screw hole. Dies are divided into circular dies, square dies, hexagonal dies and tubular dies (types of teeth) according to their shapes and uses. Among them, the circular die is the most widely used. When the pitch diameter of the processed thread exceeds the tolerance, the adjusting groove on the die can be cut to adjust the pitch diameter of the thread. The die can be installed in the die wrench to process the thread manually, or it can be installed in the die holder and used on the machine tool. The precision of the thread processed by the die is low, but due to its simple structure and convenient use, the die is still widely used in single-piece, small-batch production and repair.

Working process

Start the lathe at low speed, push the tailstock to make the die cut into the workpiece, after cutting one or two threads, you can let go, and the die drives the tailstock to automatically pull out the thread. When the required length is processed, as long as the spindle is reversed, the die pushes the tailstock back and automatically withdraws, and the processing is completed.

Using this die clamp, threading is more convenient and quicker, and there is no slippage. For larger diameter threads, it can also be used after turning a few strokes first. However, it cannot be processed due to the influence of the length of the tailstock sleeve for very long external threads.

Processing method

Start the lathe at low speed, push the tailstock to make the die cut into the workpiece, after cutting one or two threads, you can let go, and the die drives the tailstock to automatically pull out the thread. When the required length is processed, as long as the spindle is reversed, the die pushes the tailstock back and automatically withdraws, and the processing is completed.

Using this die clamp, threading is more convenient and quicker, and there is no slippage. For larger diameter threads, it can also be used after turning a few strokes first. However, it cannot be processed due to the influence of the length of the tailstock sleeve for very long external threads.

Product detail pictures:

Related Product Guide:

That has a sound business credit history, outstanding after-sales service and modern producing facilities, we have earned an superb popularity amid our buyers across the planet for Free sample for Round Die - HSS DIN345 Morse Taper Shank Drills – YUXIANG, The product will supply to all over the world, such as: Monaco, venezuela, Macedonia, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We've got established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance might be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!