OEM/ODM Manufacturer End Mill - Tungsten Carbide End Mill Cutter 4F HRC45 – YUXIANG

OEM/ODM Manufacturer End Mill - Tungsten Carbide End Mill Cutter 4F HRC45 – YUXIANG Detail:

Features

1. Applicable to rough machining.

2. High processing efficiency.

3. Good drainage and large amount of cuttings.

4. High metal cutting rate.

Advantages

1. High quality

2. Reasonable price

3. Best service

4. Excellent performance

Improvement

Nowadays, there are many requirements for coating. And we have many types for coating, so if you have any demands for this hand, you could tell us. Different Hardness based on client’s requirement. Suitable for various steel process, tooling process, Alloy Aluminium process and cast iron process. We also accept client’s requirement of non-standard size.

Company service

It is generally more efficient to use a combination of different toolpaths and tools to achieve a detailed model rather than assuming that a small tool with a smaller stepover is the only way. Often, a larger tool can achieve better finish results.

In end milling, the cutter generally rotates on an axis vertical to the workpiece. Cutting teeth are located on both the end face of the cutter and the periphery of the cutter body.

A ball nose end mill, also known as a spherical end mill or ball end mill, has a semisphere at the tool end. Ball nose end mills are used on workpieces with complex surfaces.

Choosing flat end mill vs. a ball end mill will determine the characteristics of the tooling marks (or lack thereof) on your model. Most jobs will benefit from strategic use of multiple size and shape tools for milling different features. End Mills are often used for roughing and 2D cutting and V-Bit and Ball Nose cutters are often used for finishing operations.

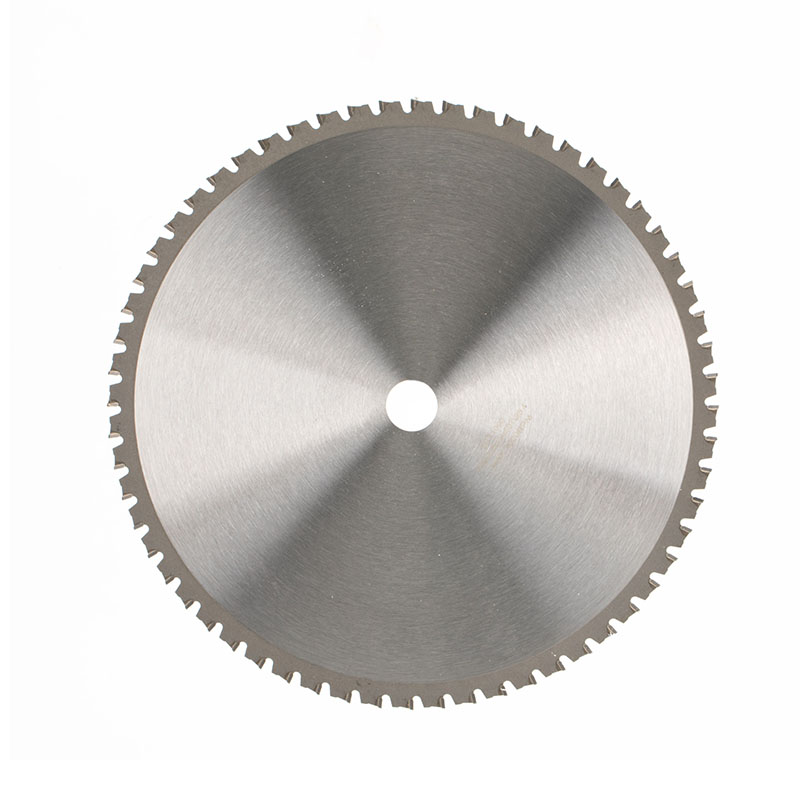

Product detail pictures:

Related Product Guide:

To fulfill the customers' over-expected fulfillment , we have now our solid staff to deliver our greatest general assistance which includes internet marketing, product sales, creating, manufacturing, excellent controlling, packing, warehousing and logistics for OEM/ODM Manufacturer End Mill - Tungsten Carbide End Mill Cutter 4F HRC45 – YUXIANG, The product will supply to all over the world, such as: Amsterdam, Portugal, Grenada, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.